What is the Caulk Yield for Teak Deck Caulking?

Our product specialists hear this question about caulk yield multiple times each business day:

“How many cartridges of caulking should I buy? “

This question about our high-performance SIS 440 Teak Deck Caulking is our most common.

The answer: Caulk yield is dependent upon seam depth and width as well as user technique, and the package size.

SIS 440 TEAK DECK CAULKING

SIS 440 is available in two packaging sizes:

Cartridge – 10.3 oz (305 ml) and Foil “Sausage” – 20 oz (592 ml)

Award-Winning SIS 440 Teak Deck Caulking

LINEAR CAULK YIELD

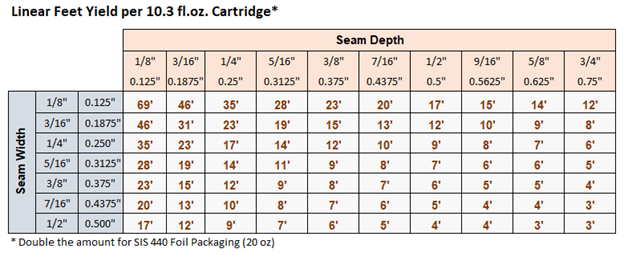

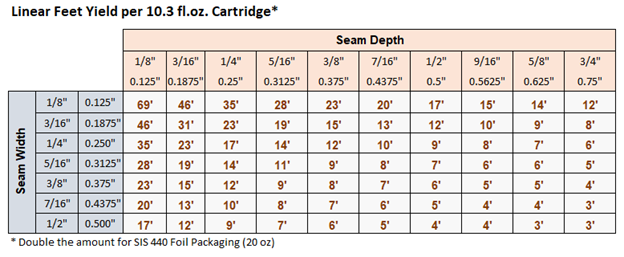

We calculated the linear caulk yield (in feet and meters) to help boat owners, builders, and repair technicians. Then we created easy-to-read tables. These amounts include a waste factor of 25%.

IMPORTANT: The linear feet or linear meters yield per package varies by user’s technique. New users commonly caulk too heavily on a first job. It takes practice to develop the skill of seam filling.

For a printable version of the above charts, click here: CAULK YIELD CHART. Please share with your colleagues.

Proper “spooning” technique is critical to ensure seams are adequately filled with SIS 440 Teak Deck Caulking as shown in this demonstration

Remember that caulking is not only decorative but has multiple functions:

- Seals the deck to prevent liquids from penetrating the sub-decking area

- Flexes and contracts with deck movement

- Functions in all temperature ranges

- Resists degradation by chemicals and UV light

Further, SIS 440 Teak Deck Caulking is an award-winning caulk and a proprietary formulation. When we couldn’t find a product that met our needs for constructing and repairing decks, we developed our own formulation.

LEARN MORE…

For more tips from our expert decking installers, please read our 16-page Caulking Application Guide. This PDF document is printable.

Read additional articles about caulking and re-seaming in these blogs:

How to Assess Teak Decking Quality

How to Inspect Teak Deck Caulking & Seams

How to Recaulk Seams

Application Techniques for Gray and White Marine Caulking

MEET OUR PRODUCT EXPERTS

Rocky Salverio (right) and Eric Young (left) are ready to assist you with your next project!

For technical and sales assistance for marine decking products, please call or email:

941-756-0600 and press “1”

ALL PRODUCTS