How to Assess Teak Decking Quality

Teak decking quality is dependent on regular inspection and maintenance. To assist boat owners, Teakdecking Systems offers these expert tips on assessing a boat’s teak decking quality. Years of enjoyment can be added to this beautiful and valuable investment with proper care.

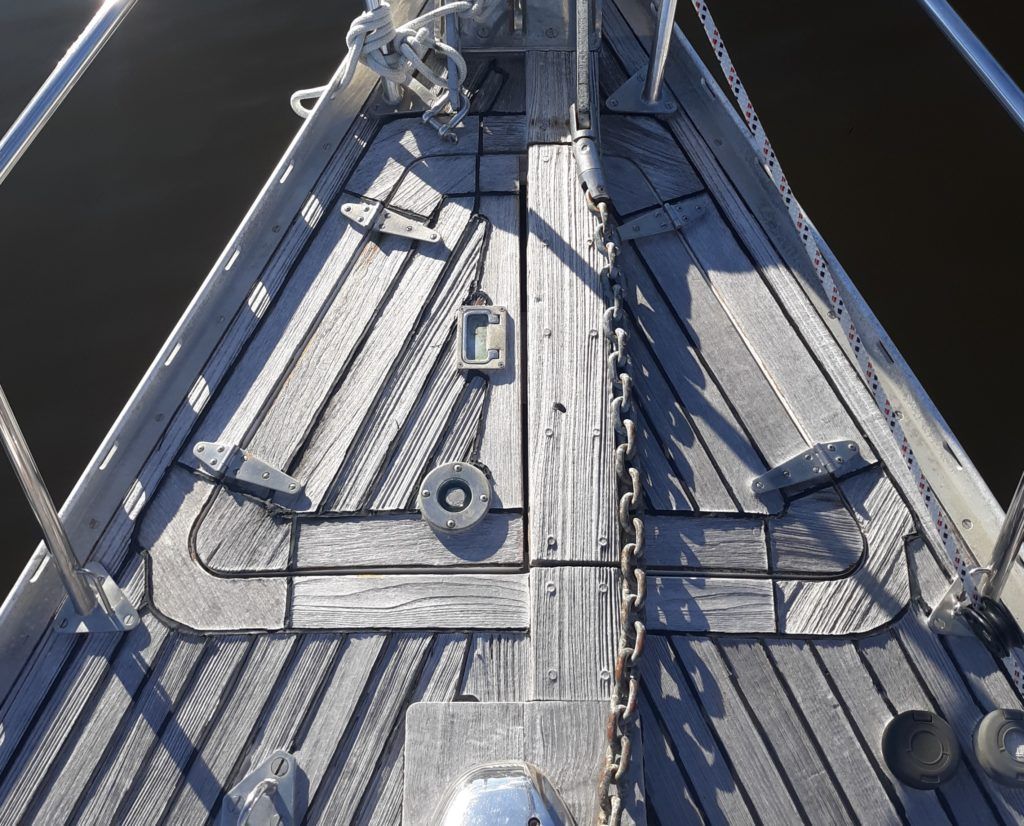

Teak Decking on Chris Craft Boat

Teak Thickness

In the design of many vintage vessels, thick teak boards were fastened directly to the frames which added structural soundness to the entire vessel. Today, modern construction methods have made the role of teak as a structural component uncommon.

Now, teak is primarily a covering to the boat’s structural subdeck. New teak decks are typically only 10 to 20 mm (3/8 to 3/4”) thick. Therefore, less wood is needed for decking.

Chris Craft Swim Platform shows Teak Thickness

Wear Rate

A teak deck typically wears away at an approximate rate of 0.5 to 1 mm of thickness per year in service. This wear rate can vary based on the following:

- Wood quality and grain orientation

- Usage

- UV degradation

- Atmospheric conditions

- Quality of deck assembly and installation

- MOST IMPORTANT – Quality of maintenance

When applying the typical 0.5 to 1mm rate of loss to a deck that is initially 10-20 mm thick, the expected useful service life will be 10 to 20 years. However, this range depends on the previously mentioned wear factors.

Perfect maintenance

will add years of life to teak decking.

Wood Grain

Quality teak decking will be assembled with vertical grain planks, which are planks with the grain running less than 45° of vertical when viewing the end of the plank.

Examine the annual growth rings have a pattern which alternates as light and dark (soft or hard wood). The widths of these teak rings are determined by the growing season. For deck use, this grain pattern should be “tight” or closely spaced. This means there is less soft wood.

Teak decking with tight vertical grain boards wear much better than those with wide grain or flat-sawn planks. So, a quality teak deck built with planks containing a tighter grain pattern (i.e., less soft wood) will have increased longevity.

Cross section view of teak panel; quarter sawn wood grain

Wood Condition

When the surface of a teak deck is badly weathered or ridged, it holds moisture and surface contaminants. This prevents proper cleaning and maintenance of the deck. A teak deck in this condition can be corrected by lightly sanding the deck to remove the ridges (if there is still enough teak thickness to make it worthwhile). As a reminder, check the depth of caulk seams and the thickness of the teak before starting.

NOTE: Periodic light sanding will keep the deck surface relatively smooth and easy to clean.

Badly weathered teak with ridges; decking is nearly unrepairable

IMPORTANT

- The use of “two-part” or acid cleaners is not recommended. They can damage the teak and caulk seams.

- Never use a pressure washer or stiff bristle brush for cleaning teak. These tools can remove the soft grain in the teak and shorten the life of the deck.

Bungs

Teak “bungs” or plugs cover the deck fasteners. If any bungs are missing look into the bung hole(s) to see how far below the surface the screw head is located. This an indicator of how much the teak has worn.

If an isolated bung is missing on a deck that is in good shape but old and thinner, it is possible to replace the bung. (Remove the screw, bore the bung hole deeper for more bonding surface, leave the screw out for more clearance, seal the screw hole, and then replace the bung.)

In some cases, the teak is fastened to the boat with screws from underneath the deck. Unfortunately, as the teak surface wears, the sharp points of the screws are exposed. Once exposed, the screw tips will damage bare feet, shoes and clothing, sails and rigging. It is not possible to grind the screw points without damaging the surrounding teak. In this case, the only fix is to remove and replace the teak deck.

Bungs on weathered teak decking

Wood Color

Teak is golden brown when first milled. Then, it naturally develops a silvery patina. This color is natural and does not mean the condition is bad.

Many boat owners like the silver patina. However, those who do not like the color will sand the teak deck to restore it to the original golden brown color. After sanding, the teak will be like new. Frequent sanding accelerates the reduction in thickness and decreases the deck’s life .

A healthy teak deck has a light silver color and clean wood. If the deck is gray, the deck needs to be cleaned with a “one-part” non-acid teak cleaner.

Sealing Teak

Since teak is an organic material it weathers over time. Oxidation causes the silver patina. This is a natural process and does not hurt the teak. However, some teak deck owners attempt to retard this process by applying various sealers or oils.

Sealing is minimally effective in the short term. Further, it increases maintenance, traps contaminants, and possibly promotes mildew growth in wet climates. This will necessitate harsh cleaning or sanding to eliminate build-up and require subsequent sealing. Most boat owners prefer to leave teak unfinished.

Caulk Seams

Read more about inspecting seams in this Teakdecking Systems article: How to Inspect Teak Deck Caulking and Seams

Questions

For questions about teak decking quality or any topic related to teak decking, contact the experts at Teakdecking Systems.

941-756-0600

yacht.services@teakdecking.com

ALL PRODUCTS